Breathing New Life into Recycled Glass

TEXT / TWELLI

PHOTOS / CHEN PO-WEI

A long-standing recycling business in Hsinchu City is exploring innovative ways to reuse discarded glass and introduce the circular economy of glass to the Taiwanese public by creating cultural spaces and offering hands-on glassmaking experiences.

Hsinchu City in northwest Taiwan has been renowned for its glass industry since the Japanese occupation period (1895~1945). The city’s first glass company was established in 1939, leveraging the area’s abundant silica sand, lime, and natural-gas resources to produce high-quality glass products. The 1950s saw rapid growth in the local glass sector, with factories built to supply glass for lamps and other industries. Enterprises later expanded into consumer products for international markets, including gifts and decorative items.

The largest glass corporation of the time, Hsinchu Glass Manufacturing Co., was founded in 1954. While primarily producing flat glass, the company opened a glass art department in 1960, marking the beginning of a thriving period for glass craftsmanship in the Hsinchu area. This golden age of glass art lasted until the late 1980s/early 1990s, after which the local industry entered a period of decline. Concurrently, other industries began to gain prominence, propelled by the establishment of the Hsinchu Science-based Industrial Park (now called the Hsinchu Science Park) in 1980.

Spring Pool Glass Studio

For those intrigued by this fascinating history, the Hsinchu City Glass Museum is a great place to start. Housed in a 1937 Japanese-era building within picturesque Hsinchu Park, the museum showcases the history and process of glassmaking, with exhibits featuring exquisite examples of glass art.

Right next to the museum is a modern three-story building you can visit to further delve into the world of glassmaking and glass art. It is home to the Spring Pool Glass Studio + The Pool, which was created to allow visitors to experience hands-on glassmaking (first floor), purchase fine glass art creations by talented designers (second floor), and enjoy fine coffee and cake (third floor).

In the third-floor café at this cultural space, Travel in Taiwan recently interviewed T. A. Wu, the visionary behind this stylish venue and son of Wu Chun-chi, founder of the Spring Pool Glass Industrial Corporation.

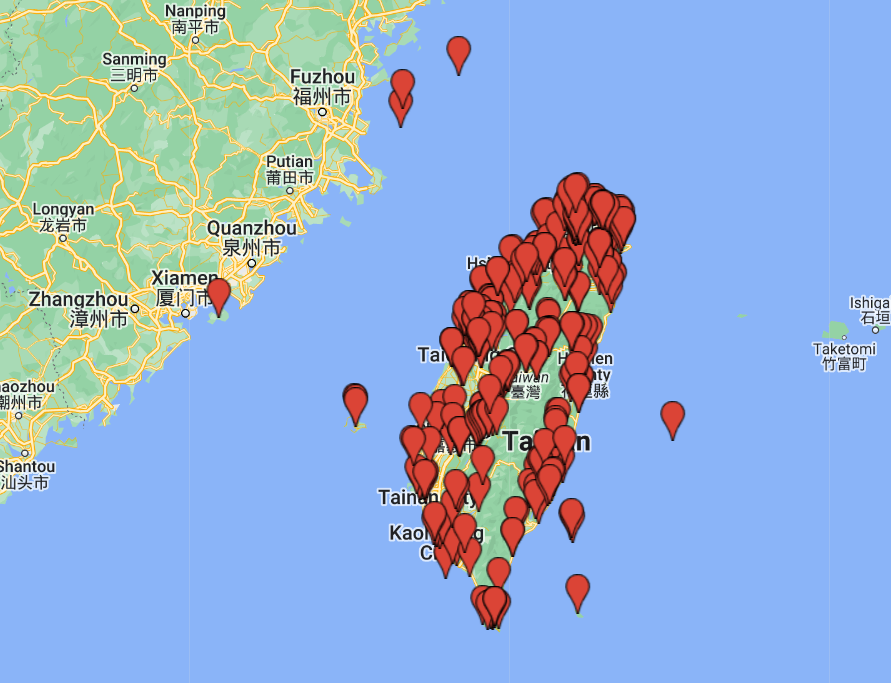

Spring Pool, established in 1961, specializes in large-scale glass recycling. The company processes about 100,000 tons of glass annually, transforming waste into new products. With six factories and 200 employees, the enterprise recycles 50~70% of Taiwan’s total glass waste.

(©Spring Pool Glass; photo by Kris Kang)

(©Spring Pool Glass; photo by Kris Kang)

Knowing the challenging nature of the business and its slim profit margins, Wu Chun-chi had hoped his son would pursue a career in a different industry. Initially, T. A. Wu embarked on a promising path, first studying in the UK and then going to work for Taiwan Semiconductor, the prominent global leader in advanced microchip production. However, concerned about his father’s advancing age and the potential closure of Spring Pool, he decided to return to the family business to inject fresh energy and diversify operations, ensuring the company’s continued growth and relevance. From the beginning, he wished to let more people know about glass recycling and create new value. “I learned a lot during my time at Taiwan Semiconductor, but I realized in 2012 that my father’s business needed transformation.”

W Glass Project

After initially focusing on the development of new products for the company, such as new building materials, in 2017 he launched the W Glass Project, aiming to merge recycling with innovative creation. The project’s first success was the “143 One Mouthful Beer Glass,” a simple yet symbolic item deeply rooted in Taiwanese culture. This 143ml glass, perfect for a mouthful of beer or juice, is commonly used in typical Taiwanese restaurants. Introduced during the Japanese era to moderate alcohol consumption amid resource scarcity, the glass has become a cultural staple. By successfully producing this iconic item from recycled materials, Wu’s project garnered numerous orders. The glass was thereafter styled in various ways, laying the groundwork for further expansion of his project.

Collaboration with leading product designers has been crucial to the success of the W Glass Project. In 2019, for example, the award-winning Taiwan design firm HMM created the amber-colored, wave-shaped W Glass. This piece exemplifies the project’s philosophy of embracing imperfections inherent in recycled glass, such as color irregularities and internal bubbles. Another notable collaboration resulted in Darts by André, designed by Taiwanese Michelin-starred chef André Chiang. This versatile set of six stackable glass plates in varying sizes is suitable for both home meals and picnics. These and many more partnerships highlight the project’s commitment to merging sustainability with innovative, functional design.

Wu has also expanded his collaborative network to include various designers, artists, and businesses, for example partnering with the prestigious Simple Kaffa coffee shop, to create an array of sparkling glass art in addition to functional pieces.

Two Pools

The creation of the above-mentioned The Pool in Hsinchu and another The Pool in the city of Tainan (located on the top floor of Tainan Art Museum Building 2) represents more accessible and permanent manifestations of Wu’s vision. Both spaces, designed by the renowned Taiwan firm Seed Spacelab, feature airy, minimalist aesthetics predominantly expressed in white. Glass and other items from recycled materials are central to both venues. In Hsinchu’s The Pool, glass objects adorn a staircase, and a large bar is constructed from glass blocks. Tainan’s version displays glass art objects and serves food and drinks in recycled-glass containers. A unique culinary highlight is the grapefruit-flavored braised pork jelly, which surprises diners with its glass-like appearance.

(©The Pool; photo by Kris Kang)

The “pool” located on the third floor of the building next to the Hsinchu City Glass Museum is a simple, square space with large windows that let in ample sunlight, and offer visitors a splendid unobstructed view of the old banyan trees in the park outside. Excellent coffee and cake are served here, and the center of the room is used as an exhibition space, showcasing various displays; during our visit, there was an exhibition introducing a photography book. Says Wu, “The idea is, while you have a cup of coffee you can also experience part of the circular economy of glass.”

On the second floor of the same building, you can purchase products made from recycled glass and other materials, crafted by designers and artists collaborating with the W Glass Project. Finally, on the ground floor, enjoy a hands-on experience in glass crafting. There are two areas: one for creating larger glass objects and another for creating smaller items such as spoons or cute animal figurines. “This is a place,” says Wu, “where you can experience glassblowing yourself, or just watch it. It’s a great place to learn about glass creation. About 80% of all people don’t know how glass is made.”

DIY Experience

Following our conversation with Wu, we explored the DIY area, where we learned to craft colorful patterned glasses. Attentive staff members guided us through each step (English instructions are available if needed). Though initially daunting, working near furnaces exceeding 1,000 degrees Celsius proved to be a safe and exhilarating 15-minute experience. The highlight was undoubtedly blowing through a long metal pipe to shape the molten glass.

The glassmaking sessions are priced at NT$980 per person, with a range of customization options offered for the workshop, including various shapes, patterns, and colors. Your finished piece requires about a day to cool and set. Participants can either arrange courier delivery in Taiwan or collect their unique creations the following day.

Spring Pool Glass Studio + The POOL

(新竹春室)

Add: No. 2, Sec. 1, Dongda Rd., Hsinchu City

(新竹市東大路一段2號)

Tel: (03) 561-1039

Website: www.glasspoolstore.com

FB: www.facebook.com/springpoolglassstudio

About the author

Twelli

Long-time resident of Taiwan, Twelli likes to go on trips around Taiwan and make videos.